Written by Audrey Woods | Produced by Andrew Zucosky

Imagine the future of robotics. Many people picture a factory staffed entirely by machines, but the reality—at least in the near term—is likely to be far more collaborative, with robots and humans working side by side. This is especially true for dexterous and complicated manufacturing tasks, where human experts will need to give input, guidance, and collaborative assistance to robots while the machines alleviate the physical toll and repetitive burden of such work.

MIT CSAIL Postdoc Mike Hagenow is developing ways for robots and humans to work together on complicated tasks, creating new interfaces for training, methods for understanding when a robot is uncertain, and options for more efficient cooperative teaming. Working with CSAIL Professor Julie Shah, he’s excited to “get the best of people and robots together to complete tasks that neither one can do on their own.”

FINDING HIS INTEREST

Even though Dr. Hagenow’s degrees are all in mechanical engineering, he developed an increasingly strong interest in computer science. As an undergraduate at Tufts University, he enjoyed working as a TA for a large introductory computer science class. Between graduating with his bachelor’s and returning to school at the University of Wisconsin for his PhD, he worked at healthcare software company Epic Systems for a few years. This solidified his interest in CS and expanded his experience with programming languages and software development.

When returning to graduate school, Dr. Hagenow’s original plan was to “go back to the engineering side.” He was interested in controls and the theory behind how we interact with the technology in our world. But he inadvertently discovered robotics—specifically human-robot interaction—as an extension of applied controls research. “The faculty at Wisconsin doing robotics at the time were very human-centered researchers. They were interested in applying robotic technologies to make peoples’ lives better, looking at work that’s very hard on people and really hard to automate.” This aligned perfectly with what Dr. Hagenow ultimately wanted to do, so he joined the robotics group and never looked back.

Now, as a postdoc in Professor Julie Shah’s Interactive Robotics Group, he’s continuing to explore ways to mechanically augment human capabilities—particularly in manufacturing—and use technology to improve workers’ lives.

ROBOT COLLABORATION: TEAMING, TEACHING, AND HUMAN-CENTERED DESIGN

“In coming to MIT,” Dr. Hagenow says, “what I wanted to do was shift my focus not on the types of problems I was working on but on the technologies I was exploring.” In his graduate studies, he was focused on more traditional approaches for how to bring together humans and robots as teams. During his time at CSAIL, he’s branched out into new areas like generative AI and modeling techniques such as diffusion policies.

For example, one key area of Dr. Hagenow’s research is understanding when a robot is uncertain and creating frameworks so the robot knows how and when to request help from a person. He and his colleagues recently published a paper introducing a new method for robots trained with generative AI to estimate when it needs help, how much help it needs, how demanding such help would be for the human in the loop, and what the most efficient form of assistance would be (if any). The idea behind this research is to make shared control—when the robot and human are working together on a task—maximally efficient, cutting down the need for a total back-and-forth handoff in task responsibility and allowing for a more collaborative approach.

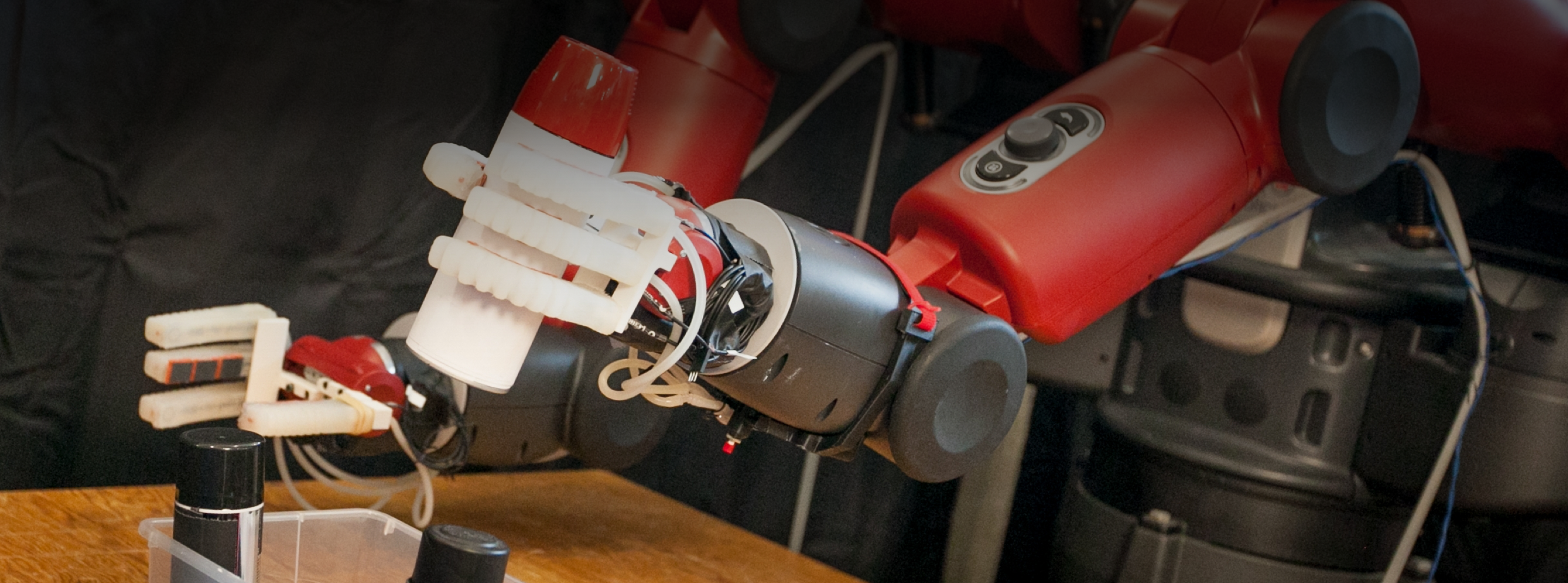

Beyond intelligent teaming, the second axis of Dr. Hagenow’s work is effective learning and teaching. “My unique lens here is that I’m very much focused on the high-contact, highly dexterous, really challenging tasks that people might do in manufacturing that are sometimes a bit underserved in terms of data collection.” To facilitate better imitation learning—where a person physically demonstrates to the robot how to do a task—Dr. Hagenow has created a specialized interface which can be added to any industrial robot without extensive additional sensing requirements. “You can imagine one of these manufacturers could buy a robot and add this tool to the end of it and then hopefully it would make it easier for them to collect data for their own tasks where they have their own ways of doing things and they want to train the robot in a ground-up way.” Dr. Hagenow has been working with the Berkshire Innovation Center in Western Massachusetts to test a prototype of this system and get feedback from workers in the field, with the ultimate aim of creating something that is effective and easy to deploy.

Working with Professor Shah, a member of MIT AeroAstro and CSAIL, Dr. Hagenow has gained insight from both the computer science and the aerospace worlds. He says the way researchers in AeroAstro think about problems is tightly linked to how safety-critical many applications in the field are, with both air and space being incredibly difficult domains. Solutions must be robust, integrate safely with people, and overcome significant challenges, such as the time delay between a ground controller and a robot on the International Space Station. Dr. Hagenow says “our lab carries that history into the way that we approach research, really trying to make sure that we understand the technologies we’re developing.” On the computer science side, he adds, “CSAIL is one of the top places to do AI and robotics research in the world. It’s remarkable how many pioneers or visionaries you might run into at the coffee machine.”

NEXT STEPS & THE FUTURE OF ROBOTICS

Dr. Hagenow will be departing CSAIL in the fall to join the faculty of the University of Wisconsin and start his own robotics group. He’s excited to join their rapidly expanding department and spin up his research in their brand new computer science building. “I plan to direct the Robot Teaching and Teaming lab, where we’ll continue to pull on these two major threads about how we can effectively get data from people and opportunities—like manufacturing—for robotic teaming.”

Even though he found the field almost by accident, Dr. Hagenow is grateful to be working in robotics. “It’s an incredibly fun research area and application that brings together the physical, embodied space of technology as well as the AI space, the algorithmic space.” He goes on, “it’s very hard to have a bad day when you’re working with a moving robot that’s doing cool tasks.”

There are many theories about what a robot-enabled future will look like, but Dr. Hagenow says the field is changing too quickly to make any solid predictions. Comparing it to a method called model predictive control, he says “you forecast the future to plan your most optimal action, take one step, and then reassess based on your new knowledge.” But one thing he’s certain about is that robots can and will change lives for the better. There are many people whose work is physically demanding, damaging, or ergonomically hazardous, and robots can help alleviate those strains and prevent injuries, surgeries, or lifelong disabilities. He says robots are “not going to be displacing workers but rather will allow them to be more effective to do work in a safer way.”

When it comes to the critical question of how those future robots and workers will interact with each other—how they’ll collaborate—Dr. Hagenow is excited to be working on what comes next.

Learn more about Dr. Hagenow on his website.